The following video presents BioAmber Corporate Video:

“BioAmber is a sustainable chemicals company producing commercial quantities of bio-based succinic acid. As global markets increasingly demand sustainable, viable and performance solutions, BioAmber is pioneering the development of a global, 100% low-carbon integrated supply chain.”

Recently, Deputy Premier Deb Matthews and BioAmber (a Montreal-based chemicals company) celebrated the official opening of the world’s largest bio-succinic acid manufacturing facility in the heart of the Sarnia-Lambton chemistry cluster.

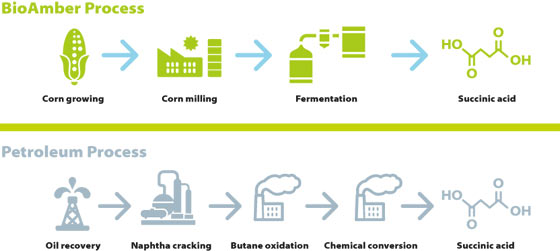

- The $141.5 million plant will produce sustainable chemicals which are renewable, greener alternatives to petrochemicals that are derived from oil.

Sustainability Life Cycle Analysis

A Carbon Neutral Footprint

“BioAmber is committed to producing chemicals in a more environmentally responsible manner. By using renewable feedstock, eliminating green house gas emissions and substantially reducing energy consumption, we are practicing greener chemistry that is sustainable. When our Sarnia plant begins production in 2015, it will have an impressive carbon footprint relative to the existing method of producing succinic acid from petroleum. Our bio-based process for making succinic acid will result in a 100% reduction in green house gas emissions and a 60% reduction in energy consumption.”

The sustainable chemicals can be used in a variety of everyday products including plastics, food additives and personal care products.

- Currently, the plant has created 60 high value jobs.

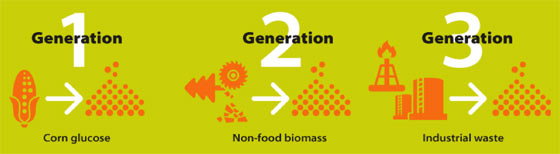

Sustainability feedstock development

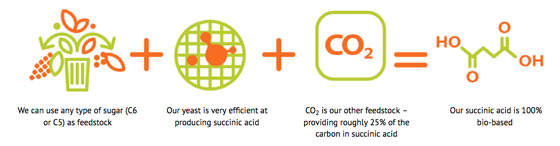

Feedstock Flexibility

“BioAmber is focused on using the most abundant, low cost sugar available, but we are also conscious of the need to be as sustainable as possible. Today, North American corn offers the most competitively priced sugar, making our succinic acid even more cost competitive. We can also use sugar from cane, beets, sorghum, wheat and tapioca to produce succinic acid. Our longer-term goal is to move to agricultural, forestry and eventually industrial waste as alternatives to traditional sugars.”

For more info about BioAmber’s greener, sustainable products and biotechnology, please visit http://www.bio-amber.com/ .

The plant will be in full commercial operation in Q3 2015, and will have a capacity to annually produce 30,000 metric tons of bio-succinic acid.

NEWS RELEASE

BioAmber Opens New Plant in Sarnia

Ontario Supporting Next Generation Manufacturers

August 6, 2015 11:00 A.M.

Ministry of Economic Development, Employment and Infrastructure

Today Deputy Premier Deb Matthews celebrated the official opening of Ontario’s newest next generation manufacturing facility in Sarnia.

BioAmber, a Montreal-based chemicals company, along with partner Mitsui, officially opened the world’s largest bio-succinic acid manufacturing facility in the heart of the Sarnia-Lambton chemistry cluster. The $141.5 million plant will produce sustainable chemicals from agricultural feedstock that can be used in a variety of everyday products including plastics, food additives and personal care products. Currently, the plant has created 60 high value jobs.

The province supported the plant with a $15 million loan through the Strategic Jobs and Investment Fund. The new plant is an anchor for the Sarnia-Lambton chemistry cluster and will raise the profile of Ontario as a world leader in the biochemical sector.

Ensuring Ontario is a world leader in next generation manufacturing is part of the government’s plan to build Ontario up. The four-part plan includes investing in people’s talents and skills, making the largest investment in public infrastructure in Ontario’s history, creating a dynamic, innovative environment where business thrives, and building a secure retirement savings plan.

Quick Facts

- The plant will be in full commercial operation in Q3 2015, and will have a capacity to annually produce 30,000 metric tons of bio-succinic acid.

- Bio-succinic acid can be used as an alternative to petrochemicals that are derived from oil.

- Global competition for manufacturing in all sectors is fierce and BioAmer looked at more than 100 sites around the world before choosing Sarnia for its new plant.

- BioAmber secured a $15 million loan from the Ministry of Economic Development, Employment and Infrastructure is providing support in the form of a Strategic Jobs and Investment Fund in September 2011.

Additional Resources

Quotes

“Today’s official opening is proof of Ontario’s commitment to the next generation of manufacturers. Ontario is proud to be supporting businesses that bring high value jobs and innovative technology to the province.”

Brad Duguid

Minister of Economic Development, Employment and Infrastructure

“The opening of the BioAmber Sarnia facility is key to the development of Sarnia’s unique bio-industrial complex, delivering good jobs, significant exports, and diverse markets for Ontario farmers with the full support of the Government of Ontario.”

Deb Matthews

Deputy Premier, President of the Treasury Board and Minister Responsible for the Poverty Reduction Strategy

“After looking at more than 100 potential sites, we chose Sarnia for this significant investment. We are excited for this facility to begin operation to help us supply our customers in the US, EU and Asia during this period of rapid growth.”

JF Huc

President and CEO, BioAmber Inc.

The following video presents BioAmber Bio-Succinic Acid Plant Construction – Sarnia, Ontario, Canada:

“BioAmber’s Sarnia manufacturing facility is the world’s largest bio-succinic acid production plant in the world. It will produces 30,000 metric tons of Bio-SA per year, with 100% greenhouse gas reduction compared to petrochemical production.

Construction began in the fall of 2013, and was mechanically completed in June, 2015. It is the result of 630,000 man hours with no time lost due to injury. Approximately 300 construction jobs and 60 full-time jobs were created by the project. The majority of plant operators are graduates from Lambton College.”

——————————————————————

You may also want to know:

- Know The Glow: 4 Tips To Spot The Golden Reflective Glow In A Child’s Photo And Save His or Her Eyes

- You’re Invited: Canon C300 Mark II Workshop at No Cost in Burbank, California August 13, 2015 (FREE admission)

- You’re Invited: “Olympus Street Photography with Mike Boening” Seminar at No Cost in Toronto, Canada August 22, 2015 (FREE admission)

- Please Urge Ontario to Raise ODSP Rates: Join ‘Stroll & Roll to Freedom’ March on July 7, 2015 UPDATE: Due to unfavourable weather forecast, this event was postponed. The new date of the march will be determined)

- “Water’s Edge”: Public Exhibition of Large-scale Photographs About Global Fresh Water Supplies: Photography Auction June 24 – July 8 + Public Opening Reception & Exhibition 9 July-16 August + V.I.P. Reception & Silent Auction 9 July + No.9 Fresh Water Symposium 10 July 2015 (Toronto: FREE admissions for Public Opening Reception & Exhibition)

- Olympus Europe Invites You: Olympus Photography Playground at No Cost in Munich 25 Aug. – 20 Sept. and Vienna 25 Sept. – 4 Oct. 2015: Borrow the OM-D Camera at No Cost (FREE admission + FREE loan of camera)

- You’re Invited: “Home Field Advantage: Toronto’s Summer Sporting Sites” Exhibition of Historic Photographs Runs to Sept.26 at No Cost: To Celebrate TORONTO 2015 Pan Am/Parapan Am Games July 10 – Aug.14 (FREE Admission for Exhibition)

- Please Help Create the World’s Largest Marine Sanctuary in the Pacific: Petition Before Aug.11, 2014

- McAfee: Superstar Soccer Players’ Screensavers and “Skills” Video Downloads are Risky to Search for Online (McAfee’s FREE SiteAdvisor)

- You’re Invited: Take Home and “Test Drive” a Leica M Camera System & Two Lenses Overnight @ No Cost: Leica Store Bellevue in Washington, USA (FREE Test Drive program)

- Newseum’s ‘Reporting Vietnam’: New Exhibit of Powerful Photos & News Footage for the 50th Anniversary of the Vietnam War: May 22, 2015 – Sept. 12, 2016 (in Washington, D.C., USA; Kids’ Admission is FREE from July 1 to Sept. 7, 2015 )

- You’re Invited: Camera Obscura at The Photographers’ Gallery (FREE admission in London, UK)

- Panasonic + UNESCO: Beautiful 2015 World Heritage Calendar App for PCs & Tablets in Five Languages (FREE App)

- Stratasys’ New Recycling Program of 3D Printing Material Canisters & Cartridges for North American Customers Starts Today: Waste Disposal at No Charge (FREE disposal & recycling program)

- Panasonic Will Share Intellectual Property to Speed Development of Internet of Things (IoT) Software & Services (Panasonic formally pledges to provide royalty-FREE access to software, patents and experience from its product ecosystem)

- Leica: M Magazine App is Available at No Cost & M Magazine No. 2 is Also Available: Dedicated to M Photography Via the Leica M Camera, Presenting Pictures Taken by Renowned Photographers (FREE M Magazine App)

- UrtheCast’s High-Resolution Camera on the ISS Captured & Released the World’s First Full-Color HD Videos of London, Boston and Barcelona from Space (UrtheCast Corp., the Earth Observation (EO) company, aims to open the world to anyone with an internet connection: FREE)

- Photography Copyright Kit (FREE)

- Nikon Canada Invites Canadian Residents to Nikon Image Space: An Online Service for Sharing Photos or Recording Memories (FREE online service for all Canadian residents to share & record images: FREE two GB of storage for everyone and Nikon camera owners get an extra FREE 18 GB of storage.)

- New NIKON IMAGE SPACE App Renewal at No Charge: Benefits Include Seeing Images Larger & Browsing Images Stored on Your Smart Device (FREE online photo sharing service + FREE renewal of smart device app for “NIKON IMAGE SPACE”)

- Canon’s Cloud-based Image Management Service, irista: No Cost for Up to 15GB + New Updates are Now Live (FREE 15GB of cloud storage space with full irista functionality)

- Canon Europe Acquires Lifecake – Baby Photo Timeline: A Photo-sharing App for Families to Create Photo & Video Timelines (Lifecake is available FREE for iPhone, iPad and Android)

- You’re Invited to the New Leica Fotopark: A Photo Platform for Passionate Photographers to Discover, Exchange, Organise, Create [Registration on www.leica-fotopark is FREE, as is the use of the platform for data volumes of up to ten gigabytes (GB)]

- You’re Invited: Download Leica Fotografie International App for iPhone, iPod Touch, iPad and Android

- Scarborough Subway Project Assessment-Line 2 Extension: Public Consultations Jan.31 & Feb.2, 2015 + Online Feedback

- Panasonic’s Medical Delivery Robot “HOSPI” in the “Center for Advanced Medical Robotics” in Thailand

- Celebrate: Fort York Visitor Centre (five new exhibitions inside the new Visitor Centre in 2014 – 2015)